Be yourself; Everyone else is already taken.

— Oscar Wilde.

This is the first post on my new blog. I’m just getting this new blog going, so stay tuned for more. Subscribe below to get notified when I post new updates.

Be yourself; Everyone else is already taken.

— Oscar Wilde.

This is the first post on my new blog. I’m just getting this new blog going, so stay tuned for more. Subscribe below to get notified when I post new updates.

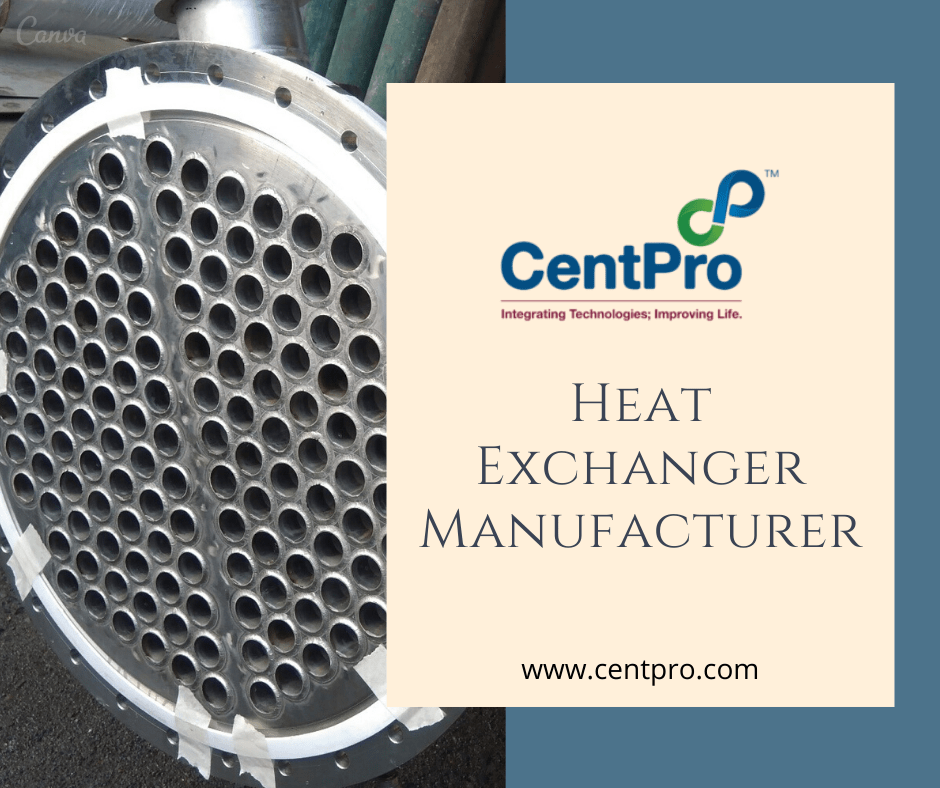

ISO 9001 Certified Company: CentPro Engg. leading manufacturers and suppliers of all types of heat exchangers in India. Our most commonly supplied Shell & Tube Heat Exchangers includes Condensers, Reboilers, Kettle Type Heat Exchangers, Evaporators, Calendria, etc. with TEMA type configurations like BEM, AEL, BKU, etc. in all categories of TEMA Class R, C, and B either vertical or Horizontal in Stainless Steels, Carbon Steels, Boiler Quality Carbon Steel, Low Temperature Service Carbon Steel, Alloy steels, H2S service which calls for NACE & HIC resistant materials, etc.

Manufacturer and Supplier of Shell and Tube Heat Exchangers

Special features of Centpro’s Manufactured Heat-Exchanger

ATFD Features

Pilot Plant (ATFD System)

We Centpro Engineering Private Limited, provide Pilot Plant Agitated Thin Film Dryers (ATFD) for taking trials at customers’ place, which enables our clients to validate the designed process. Also, we conduct a test of industrial effluent in our well-equipped Laboratory to study the behavior of a process before using it on a large industrial scale and thus assuring the performance. This distinct view of satisfying customer’s needs makes us renowned solution provider.

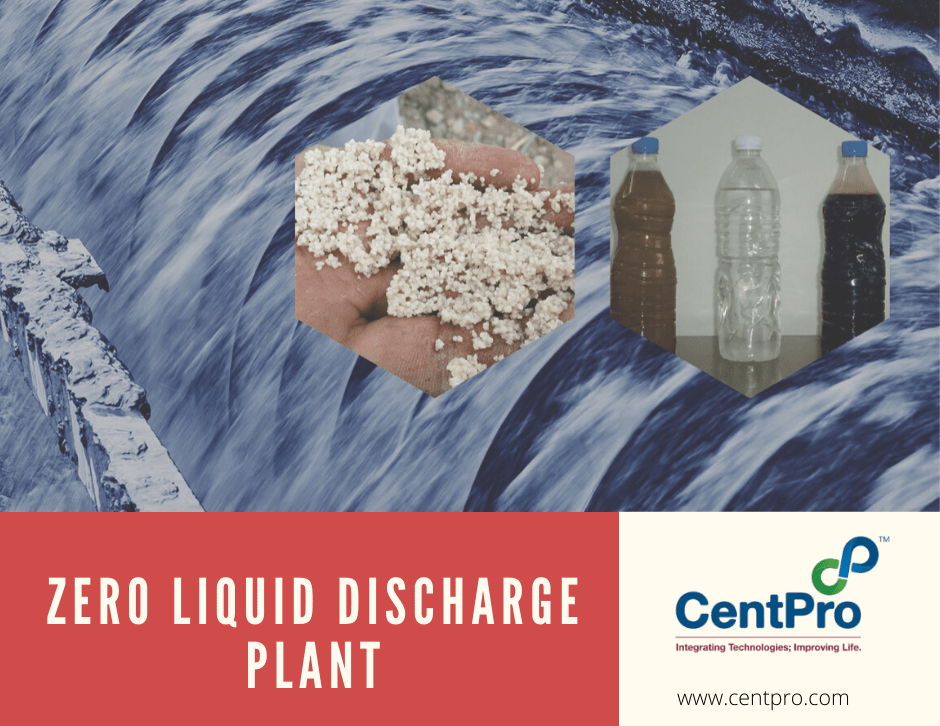

“Zero Liquid Discharge System” can produce a useable stream of water from industrial effluent / waste water suitable for reuse in plant for various applications and discharging concentrate stream to produce baggable solids / powder / salts which is then sent for disposal / incineration.

To achieve the aim of Zero Liquid Discharge Plant, Initially effluent is treated in series of variety of well known water treatment processes like primary, secondary & tertiary treatment OR as per effluent characteristics it is directly treated in thermal methods. In tertiary treatment RO is most commonly used method. After RO there is still large amount of water left in the reject stream and which will be evaporated in thermal treatment methods and thereby only discharging solid

Thus whatever water present in the effluent is recovered as useful water and solids present are discharged in the form of baggable solids / powder / salt which is sent for disposal.

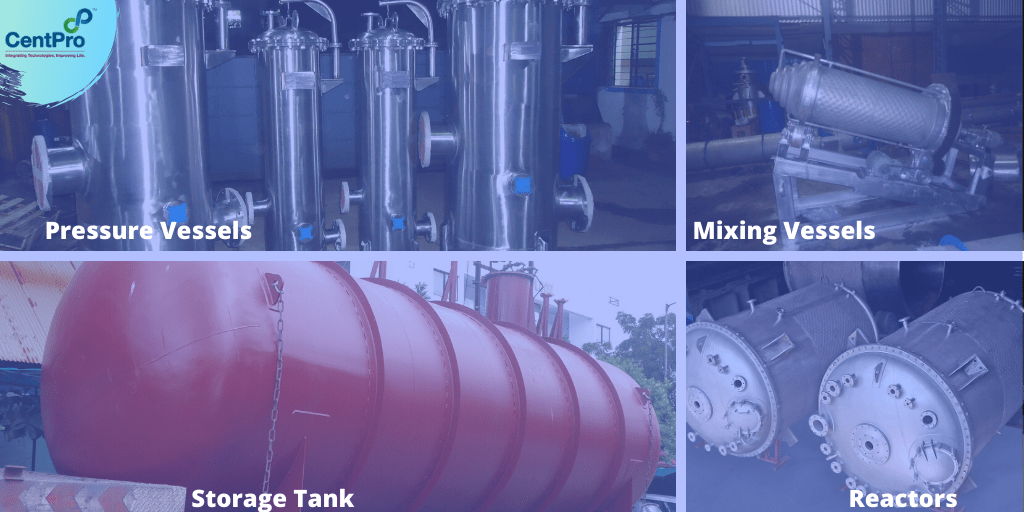

Centpro Engineering Private Limited takes incredible presenting Itself as new generation association in the field of Design, Engineering, Manufacturing and Supply of Process Chemical Equipment for different modern applications. We are worked in assorted scope of redid process equipment manufacturer in India like Pressure Vessels, Jacketed or Limpeted Reaction vessels, Heat Exchangers, Distillation Columns, Storage Tanks, and so on to different industry segments, for example, Oil and Gas, Petro Chemicals, Food, Beverages, Milk, Edible Oil, Chemical and Pharmaceuticals Industries and additionally going along to Indian and International Standards. We also provide a customized turnkey solution from Concept to Commissioning plants relating to Evaporation Systems, Dairy plants, and so on which incorporates point by point designing of turnkey plant, Procurement, Fabrication, Erection and Commissioning of plant and procedure types of gear at site.

1 – Storage Tanks

We Manufacture & Supply all types of Vertical and Horizontal Storage Tanks for various industrial applications conforming to API-650, API-620 standards, etc. We have supplied the tanks in wide range of capacities from 5000 Ltrs to 150,000 Ltrs capacity in Stainless Steel material construction with lugs supports/ Skirt Supports with Top conical and flat bottom end, top and bottom Conical ends with or without half pipe jackets on bottom conical ends, etc. based on customer’s process and installation requirements.

2 – Heat Exchangers

Our most commonly supplied Shell & Tube Heat Exchangers includes Condensers, Reboilers, Kettle Type Heat Exchangers, Evaporators, Calendria, etc. with TEMA type configurations like BEM, AEL, BKU, etc. in all categories of TEMA Class R, C, and B either vertical or Horizontal in Stainless Steels, Carbon Steels, Boiler Quality Carbon Steel, Low Temperature Service Carbon Steel, Alloy steels, H2S service which calls for NACE & HIC resistant materials, etc.

3 – MIXING VESSELS

The design of pharmaceutical and chemical reactors has to be catered of several issues which needs customization so as to meet the customer’s specific process requirements. Robust design of process reaction vessels offered with Various Types of Agitators such as Anchor, Turbine, Mig , Hydrofoil, Propeller, Pitched, Disc, Paddles, Helical and Contra Mixer etc. are capable of producing desired turbulence.

4 – PRESSURE VESSELS

We are specialized and committed in manufacturing and supplying technologically advanced range of quality pressure vessels in various Capacities with reliability upon design as per customer’s requirements and in conformity to National and International codes and guidelines which includes ASME Section VIII Division 1, API-650, API-620, PD5500, etc

This is an example post, originally published as part of Blogging University. Enroll in one of our ten programs, and start your blog right.

You’re going to publish a post today. Don’t worry about how your blog looks. Don’t worry if you haven’t given it a name yet, or you’re feeling overwhelmed. Just click the “New Post” button, and tell us why you’re here.

Why do this?

The post can be short or long, a personal intro to your life or a bloggy mission statement, a manifesto for the future or a simple outline of your the types of things you hope to publish.

To help you get started, here are a few questions:

You’re not locked into any of this; one of the wonderful things about blogs is how they constantly evolve as we learn, grow, and interact with one another — but it’s good to know where and why you started, and articulating your goals may just give you a few other post ideas.

Can’t think how to get started? Just write the first thing that pops into your head. Anne Lamott, author of a book on writing we love, says that you need to give yourself permission to write a “crappy first draft”. Anne makes a great point — just start writing, and worry about editing it later.

When you’re ready to publish, give your post three to five tags that describe your blog’s focus — writing, photography, fiction, parenting, food, cars, movies, sports, whatever. These tags will help others who care about your topics find you in the Reader. Make sure one of the tags is “zerotohero,” so other new bloggers can find you, too.