Centpro Engineering Private Limited takes incredible presenting Itself as new generation association in the field of Design, Engineering, Manufacturing and Supply of Process Chemical Equipment for different modern applications. We are worked in assorted scope of redid process equipment manufacturer in India like Pressure Vessels, Jacketed or Limpeted Reaction vessels, Heat Exchangers, Distillation Columns, Storage Tanks, and so on to different industry segments, for example, Oil and Gas, Petro Chemicals, Food, Beverages, Milk, Edible Oil, Chemical and Pharmaceuticals Industries and additionally going along to Indian and International Standards. We also provide a customized turnkey solution from Concept to Commissioning plants relating to Evaporation Systems, Dairy plants, and so on which incorporates point by point designing of turnkey plant, Procurement, Fabrication, Erection and Commissioning of plant and procedure types of gear at site.

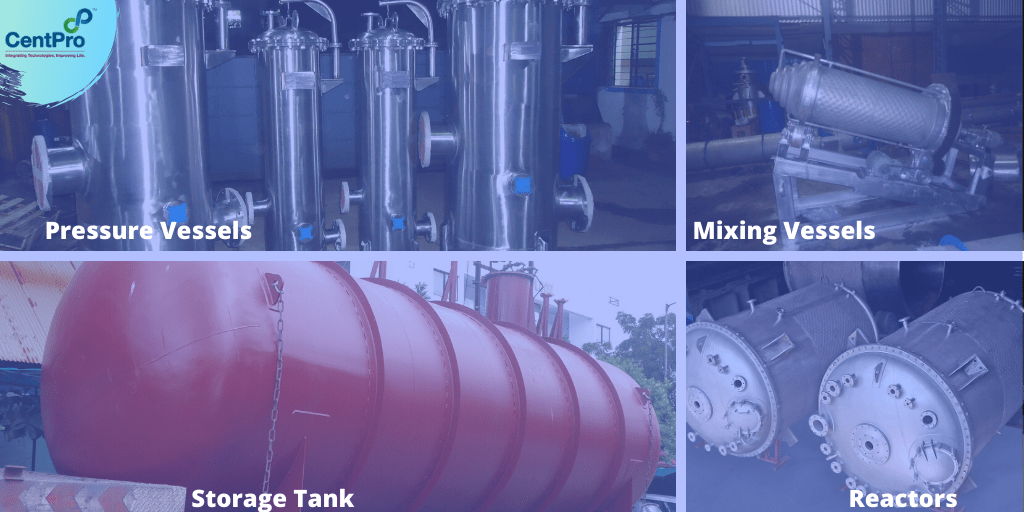

List of Process Equipments

1 – Storage Tanks

We Manufacture & Supply all types of Vertical and Horizontal Storage Tanks for various industrial applications conforming to API-650, API-620 standards, etc. We have supplied the tanks in wide range of capacities from 5000 Ltrs to 150,000 Ltrs capacity in Stainless Steel material construction with lugs supports/ Skirt Supports with Top conical and flat bottom end, top and bottom Conical ends with or without half pipe jackets on bottom conical ends, etc. based on customer’s process and installation requirements.

2 – Heat Exchangers

Our most commonly supplied Shell & Tube Heat Exchangers includes Condensers, Reboilers, Kettle Type Heat Exchangers, Evaporators, Calendria, etc. with TEMA type configurations like BEM, AEL, BKU, etc. in all categories of TEMA Class R, C, and B either vertical or Horizontal in Stainless Steels, Carbon Steels, Boiler Quality Carbon Steel, Low Temperature Service Carbon Steel, Alloy steels, H2S service which calls for NACE & HIC resistant materials, etc.

3 – MIXING VESSELS

The design of pharmaceutical and chemical reactors has to be catered of several issues which needs customization so as to meet the customer’s specific process requirements. Robust design of process reaction vessels offered with Various Types of Agitators such as Anchor, Turbine, Mig , Hydrofoil, Propeller, Pitched, Disc, Paddles, Helical and Contra Mixer etc. are capable of producing desired turbulence.

4 – PRESSURE VESSELS

We are specialized and committed in manufacturing and supplying technologically advanced range of quality pressure vessels in various Capacities with reliability upon design as per customer’s requirements and in conformity to National and International codes and guidelines which includes ASME Section VIII Division 1, API-650, API-620, PD5500, etc